Every project is a new technical challenge.

At AMCO we tackle it with you, with precision and commitment.

We don’t just machine parts. We integrate engineering, machining, quality, and automation to deliver fully tailored solutions for our clients.

Each service is carried out with technical rigor, industrial vision, and a firm commitment to delivering only what meets our highest standards.

Discover how we work and what we can bring to your project.

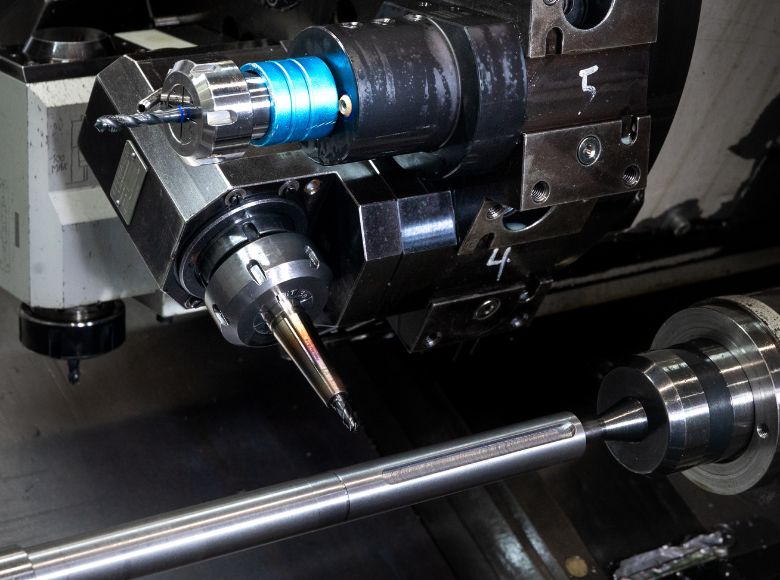

Prototypes, small and large production runs

From prototypes to large production runs, we design and manufacture parts with CNC precision and process efficiency.

We adapt to any volume and complexity.

CAD design, technical advice and optimization

We collaborate from the initial design stage to optimise functionality, costs, and processes.

We combine technical expertise with human guidance to make your project viable and profitable.

Technical and functional finishes

We apply technical treatments and surface finishes that ensure the mechanical, aesthetic, and durability of each part.

Anodizing, painting, vibration, and more.

100% dimensional control and full traceability

Full 3D verification and complete traceability for every part.

We ensure compliance with drawings, tolerances, and materials through accurate documentation and dimensional control.

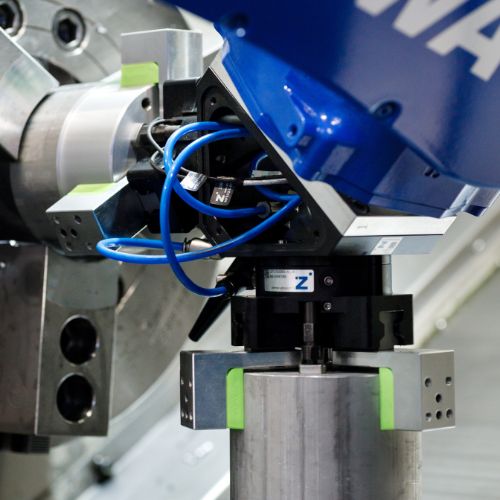

High repeatability and efficiency for large production runs

Precision and efficiency in every weld bead. Robotic welding with CNC turning machines (1800 x 2000 mm) for large production runs, and high-precision manual welding for custom parts.

TECHNOLOGY AND PRODUCTION

At AMCO, innovation is part of our DNA. We embrace cutting-edge technology and automation to ensure efficient, safe, and precise production processes.

Thanks to our CNC machinery, robotic systems, and integrated verification protocols, we are able to adapt to each client with maximum flexibility and reliability.