Each step matters.

Each part, a precise system.

At AMCO, technology is the foundation of our production system.

We integrate engineering, machining, automation, and quality control into a seamless and precise process.

Each part is a new opportunity for technical excellence, and each client is a challenge we embrace with commitment and long-term vision.

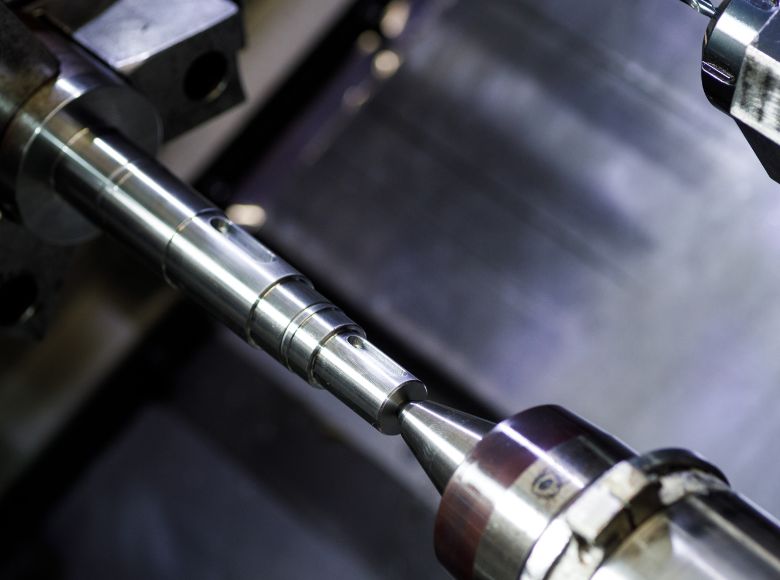

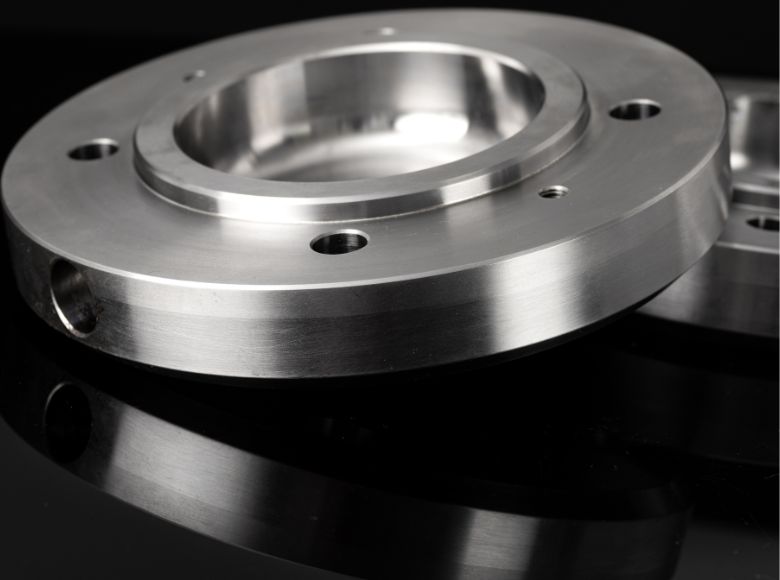

PRECISE, VERSATILE AND AUTOMATED PRODUCTION

Processes such as CNC milling, automated turning, and robotic welding are used to meet the needs of highly technical projects, whether single-parts or large-scale production.

PRODUCTION

Versatile machining centers for high-complexity parts.

For long production runs with high repeatability.

We combine precision and adaptability. Robotic welding with 2 CNC positioners (1,800 × 2,000 mm capacity).

We bring ideas to life quickly and flexibly through 3D printing. This service allows us to validate designs, run fitting and functionality tests, and reduce time and costs in the early development stages. Ideal for prototypes and one-off parts.

TECHNICAL FINISHES THAT MAKE THE DIFFERENCE

We apply treatments that enhance the durability, appearance, and functionality of each part.

FINISHED

We optimize the hardness and strength of parts through controlled heat treatment processes, tailored to each material's properties and final working conditions.

We apply protective and decorative coatings, with durable finishes designed for demanding environments (food industry, chemical, outdoor, etc.).

We protect aluminium surfaces with a technical and aesthetic finish, available in various colours, enhancing resistance to corrosion and wear.

We apply a metallic layer that enhances mechanical strength and provides an elegant, highly durable finish.

Vibratory processes that remove sharp edges and surface irregularities to refine the finish and prepare the part for assembly or final use.

Total dimensional control, with no margin of error

We measure, verify, and document each part to ensure exact tolerances and quality with every delivery.

QUALITY

Three-Dimensional Measuring Arm

Enables high-precision 3D dimensional inspections, verification of complex structures, and generation of detailed reports for the client.

Roughness tester

We measure surface finish using calibrated instruments to ensure roughness meets the project’s technical requirements.

Every part that leaves our workshop has been thoroughly inspected. Whether it's a short run or a large-scale production, we ensure maximum reliability.

Technical materials, guaranteed performance

We work with technical metals and engineering plastics tailored to each sector and functional need.

MATERIALS

Steels, technical steels, stainless steels (304, 316, 310, 420, Alloy 20, etc.), aluminum, bronze, etc.

Common and technical steels: For parts that require strength, durability, or specific heat treatments.

Stainless steels (304, 316, 310, 420, Alloy 20, etc.): Ideal for demanding environments, such as the food industry, chemical, or medical sectors.

Aluminum: Lightweight and highly machinable, widely used in automotive or packaging industries.

Bronze and other special metals: Used in high-precision components, bearings, or specific applications.

PC, POM, PA, PP, PEEK, ABS, DESLIDUR, PET P, ...

Non-metallic materials that allow the production of functional parts with wear-resistance, chemical sstability, and low friction. Ideal for machinery components, guides, gears, or parts requiring lightness and precision.

Every process, every material, and every control are designed to ensure your parts perform their function without error.

At AMCO we machine,

weld, assemble and verify parts so your operations never stop.

Specialists in CNC machining and industrial boilermaking, with advanced quality control and a team that supports you from start to finish.

We are familiar with the standards and requirements of sectors such as food, cosmetics, packaging, automotive, defense, and petrochemicals.

We tailor each technical solution to the logistics, quality, and traceability requirements of your process.

Precision, compliance, and reliability. That’s AMCO.

Location

- C/Mas Resplandis, 17D

- 17213 Esclanyà (GIRONA)

Office hours

- Morning: 08am - 13pm

- Afternoon: 15pm - 18pm